Centrifugal Pumps

Centrifugal Pumps are by far the most widely used of fluid handling pump types due to its design simplicity, durability, versatility and economics. More than 85% of all the installed pumps in any typical factories/plants are centrifugal pumps. The distinctive features and unique operating characteristics of centrifugal pumps will be further discussed below.

A centrifugal pump is made up of two main components:

- A rotating element consists of impeller and shaft;

- A stationary element including casing, stuffing box and bearing housing.

The impeller vanes are exploited to impart energy to the fluid through centrifugal force.

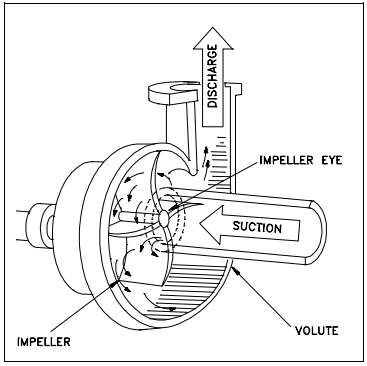

Figure 3. Centrifugal Pump

Figure 3 illustrates a simplified diagram how a typical centrifugal pump operates. In a centrifugal pump, fluid is introduced through the casing inlet to the eye of the impeller where it is picked up by the impeller vanes. As the impeller rotates, the rotary motion of the impeller imparts a rotating motion to the fluid, forcing it to the outer periphery of the impeller vanes where it is collected in the pump volute. The volute is the portion of the pump casing that expands in cross-sectional area as it wraps around the pump casing. The casing volute collects the fluid discharged from the edge of the impeller at high velocity and gradually reduces the fluid velocity by increasing the flow area. This converts the velocity energy to pressure energy prior to discharging the fluid to the system.